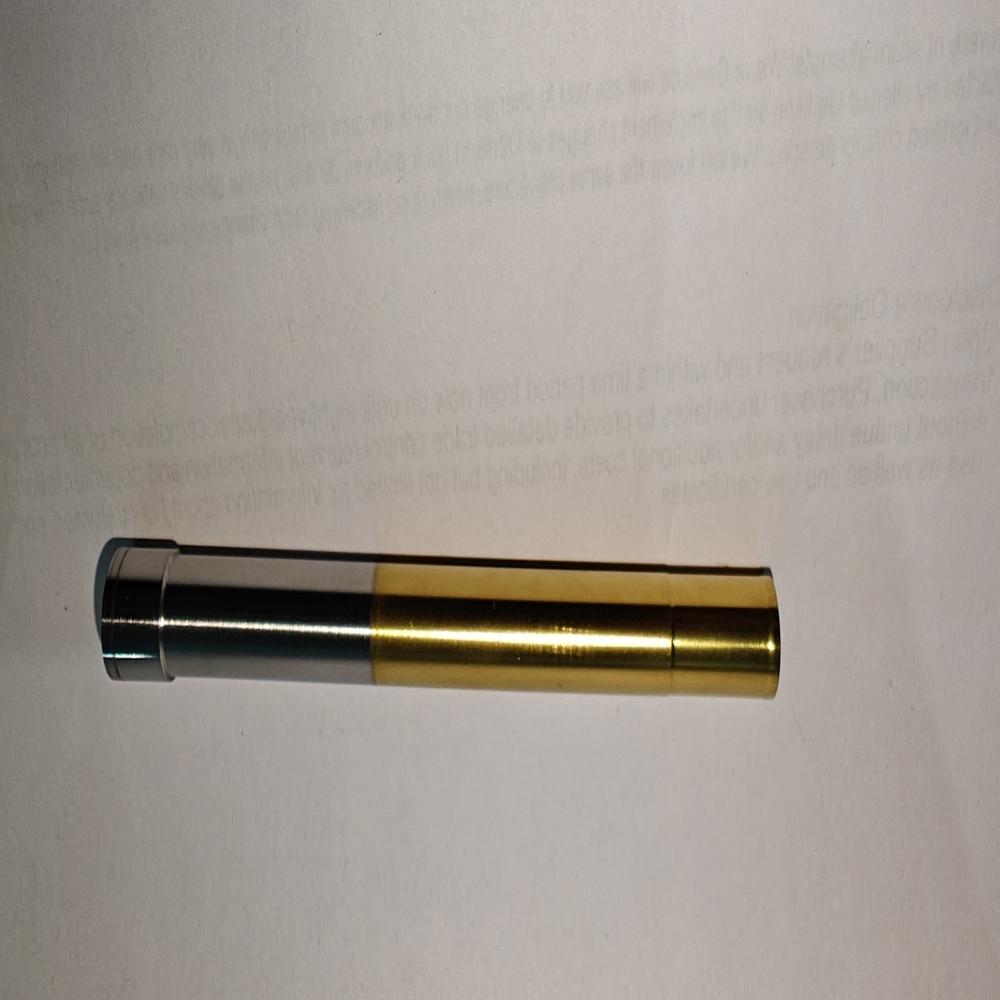

HOLE PUNCH DIA 10/9.15/9.10x110MM WITH PVD TIN COATING HSS M42

HOLE PUNCH DIA 10/9.15/9.10x110MM WITH PVD TIN COATING HSS M42 Specification

- Shape

- Bar

- Product Type

- HSS Punches

- Size

- 10/9.15/9.10x110MM

- Usage

- Industrial

- Hardness

- High

- Material

- High Speed Steel

HOLE PUNCH DIA 10/9.15/9.10x110MM WITH PVD TIN COATING HSS M42 Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 8 Days

- Sample Available

- No

- Main Domestic Market

- All India

About HOLE PUNCH DIA 10/9.15/9.10x110MM WITH PVD TIN COATING HSS M42

-

HSS M42:

- Contains 8-10% cobalt, providing excellent hardness, toughness, and heat resistance.

- Suitable for punching through hard metals, including stainless steel, titanium, and tool steels.

-

PVD TiN Coating:

- Enhances wear resistance and reduces friction for smoother operation.

- Provides high-temperature stability, allowing prolonged high-speed usage.

- Increases tool life and durability, ensuring consistent performance.

- Longer Tool Life: The PVD TiN coating significantly enhances durability.

- High Precision & Accuracy: Ensures clean, burr-free holes with minimal deformation.

- Excellent Heat & Wear Resistance: Withstands intense heat and pressure during punching.

- Reduced Friction & Material Adhesion: Enhances efficiency and tool longevity.

Hole Punch 10/9.15/9.10 110mm with PVD TiN Coating, HSS M42

1. Overview:

This high-speed steel (HSS M42) hole punch is designed for precision punching in tough materials, ensuring high durability, excellent wear resistance, and superior heat resistance. The PVD TiN (Titanium Nitride) coating enhances tool longevity and performance by reducing friction and increasing hardness.

2. Technical Specifications:

| Parameter | Details |

|---|---|

| Material | HSS M42 (High-Speed Steel, M42 Grade) |

| Diameters | 10.00 mm / 9.15 mm / 9.10 mm |

| Overall Length | 110 mm |

| Coating | PVD TiN (Titanium Nitride) |

| Hardness | Approx. 67-70 HRC |

| Wear Resistance | High (due to TiN coating) |

| Heat Resistance | Excellent (M42 can withstand up to 1100C) |

| Surface Hardness (with TiN) | 2300 HV (Vickers Hardness) |

3. Material & Coating Details

4. Applications

Metal Fabrication & Sheet Metal Processing Ideal for punching stainless steel, aluminum, and hardened alloys.

Automotive & Aerospace Manufacturing Used in precision punching of high-strength components.

Industrial Machining & Engineering Ensures smooth, accurate punching with minimal tool wear.

Heavy-Duty Manufacturing Suitable for high-speed and high-pressure punching operations.

5. Benefits

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Punch Category

HEXAGONAL FORGING PUNCH DIA 7.50/ HEX A/F 6.10 x 85MM WITH PVD TIN COATING HSS M42

Price 350.0 INR / Unit

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : Stainless Steel

Shape : Round

Hardness : High

HOLE PUNCH DIA 12/9.30/9.45x95MM WITH PVD TIN COATING HSS M42

Price 587.00 INR / Unit

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : High Speed Steel

Shape : Bar

Hardness : High

HEXAGONAL FORGING PUNCH DIA 11.90/ HEX A/F 8.10 x 90MM WITH PVD TIN COATING HSS M42

Price 590.0 INR / Unit

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : Stainless Steel

Shape : Round

HOLE PUNCH DIA 10/9.15/5.10x110MM WITH PVD TIN COATING HSS M42

Price 581.00 INR / Unit

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : High Speed Steel

Shape : Bar

Hardness : High

Send Inquiry

Send Inquiry