NUT FORMER PUNCH DIA 16.90/15.90/14.65/13.40/8.40x102MM WITH ALCRONA BLACK COATING

NUT FORMER PUNCH DIA 16.90/15.90/14.65/13.40/8.40x102MM WITH ALCRONA BLACK COATING Specification

- Size

- Different Available

- Color

- Black coated

- Usage

- Industrial

NUT FORMER PUNCH DIA 16.90/15.90/14.65/13.40/8.40x102MM WITH ALCRONA BLACK COATING Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 20 Days

- Main Domestic Market

- All India

About NUT FORMER PUNCH DIA 16.90/15.90/14.65/13.40/8.40x102MM WITH ALCRONA BLACK COATING

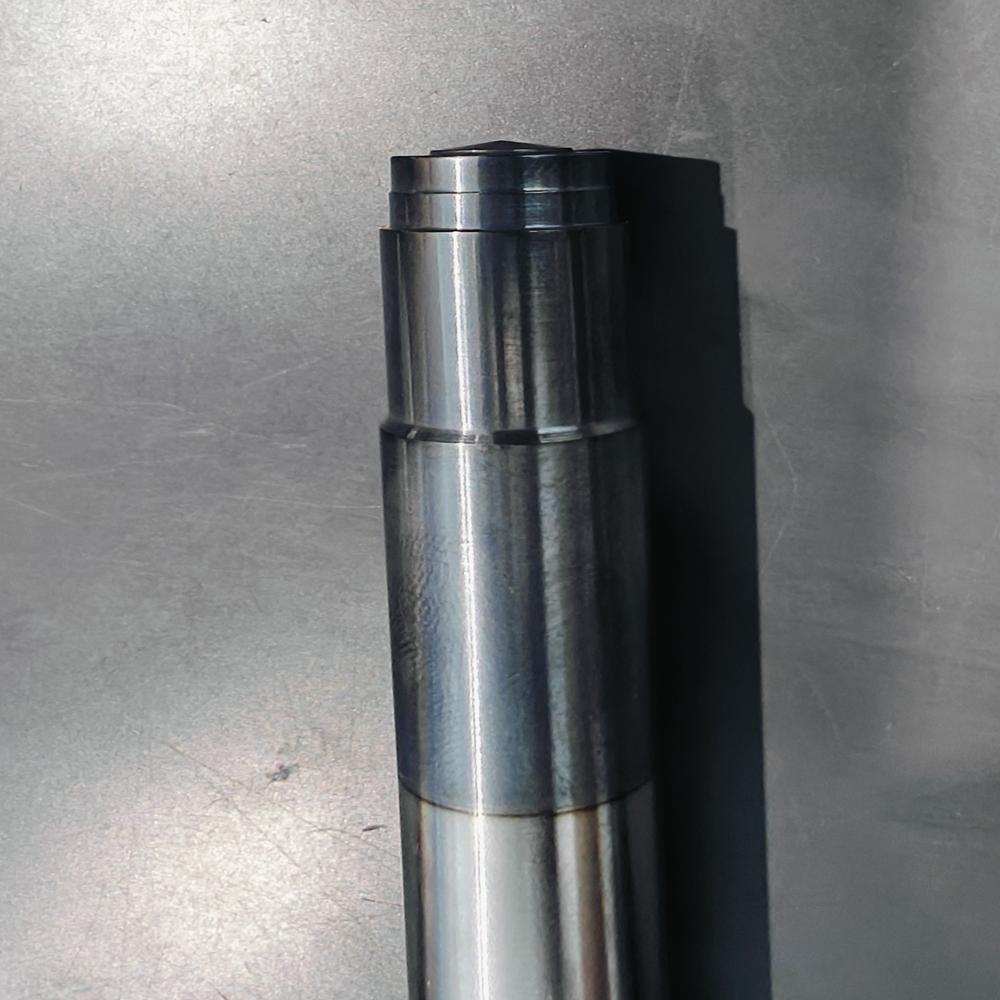

Nut Former Punch 16.90/15.90/14.65/13.40/8.40 102mm with Alcrona Black Coating

1. Overview:

This Nut Former Punch is a high-performance tool designed for cold and warm forging applications in fastener manufacturing. Made from premium high-speed steel (HSS or PM-grade steel, typically HSS M42 or equivalent), it features an Alcrona Black Coating, which provides exceptional wear resistance, heat stability, and extended tool life in high-speed forming applications.

2. Technical Specifications:

| Parameter | Details |

|---|---|

| Material | High-Performance HSS (M42 or Equivalent) |

| Diameters | 16.90 mm / 15.90 mm / 14.65 mm / 13.40 mm / 8.40 mm |

| Overall Length | 102 mm |

| Coating | Alcrona Black Coating (Advanced PVD Coating) |

| Hardness | Approx. 68-72 HRC |

| Coating Hardness | ~3200 HV (Vickers Hardness) |

| Wear Resistance | Extremely High (due to Alcrona Coating) |

| Heat Resistance | Excellent (withstands up to 1100C) |

| Friction Coefficient | Low (minimizes material adhesion and sticking) |

3. Material & Coating Details

-

High-Speed Steel (HSS M42 or Equivalent):

- Contains 8-10% cobalt, ensuring high strength, wear resistance, and toughness.

- Ideal for cold and warm forging of nuts, bolts, and fasteners.

- Withstands high-pressure and impact forces without deformation.

-

Alcrona Black Coating (PVD Advanced Coating):

- Superior wear and oxidation resistance, perfect for high-load applications.

- Enhances thermal stability, allowing high-speed punching without loss of hardness.

- Reduces friction and material adhesion, improving efficiency and tool longevity.

- Ideal for forming high-strength alloys, stainless steel, and hardened materials.

4. Applications

Nut & Bolt Manufacturing Designed for high-precision cold and warm forming.

Automotive & Aerospace Fasteners Used in high-strength nut forming processes.

Industrial Machining & Forging Ensures high-speed, high-accuracy nut production.

Heavy-Duty Metal Forming Performs well under extreme pressure and wear conditions.

5. Benefits

- Extreme Wear & Heat Resistance: Alcrona Black Coating enhances longevity and durability.

- High-Precision Forming: Provides consistent and accurate shaping of nuts.

- Superior Performance in High-Speed Applications: Reduces tool wear in continuous production cycles.

- Reduced Friction & Material Adhesion: Improves efficiency and prevents galling/sticking.

6. Comparable Alternatives

| Alternative | Key Benefits |

|---|---|

| TiN Coating (Titanium Nitride) | Good wear resistance but less heat-resistant than Alcrona. |

| TiAlN Coating (Titanium Aluminum Nitride) | Better for extreme heat but slightly lower wear resistance. |

| DLC Coating (Diamond-Like Carbon) | Superior friction reduction but lower thermal stability. |

| Uncoated HSS M42 | Same base material but lacks coating benefits like wear and heat resistance. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Punch Category

HEXAGONAL FORGING PUNCH DIA 7.50/ HEX A/F 6.10 x 85MM WITH PVD TIN COATING HSS M42

Price 350.0 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Usage : Industrial

Material : Stainless Steel

Shape : Round

HOLE PUNCH DIA 5.90/5.50/4.90x68MM WITH PVD TIN COATING HSS M42

Price 434.00 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Usage : Industrial

Material : High Speed Steel

Shape : Bar

HOLE PUNCH DIA 10/9.15/9.10x110MM WITH PVD TIN COATING HSS M42

Price 580.0 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Usage : Industrial

Material : High Speed Steel

Shape : Bar

HOLE PUNCH DIA 12.90/11.90/6.75/6.90x101MM WITH PVD TIN COATING HSS M42

Price 605.00 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Usage : Industrial

Material : High Speed Steel

Shape : Bar

Send Inquiry

Send Inquiry