Call: 08045801570

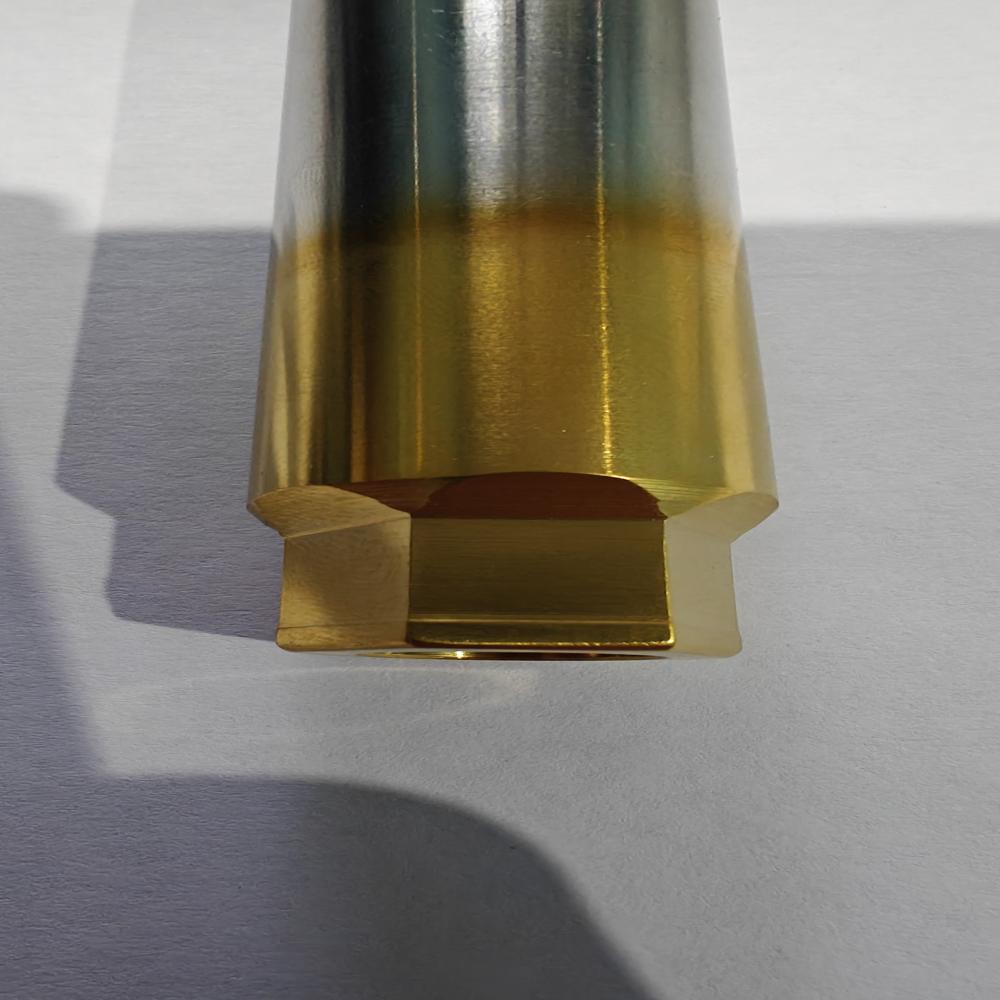

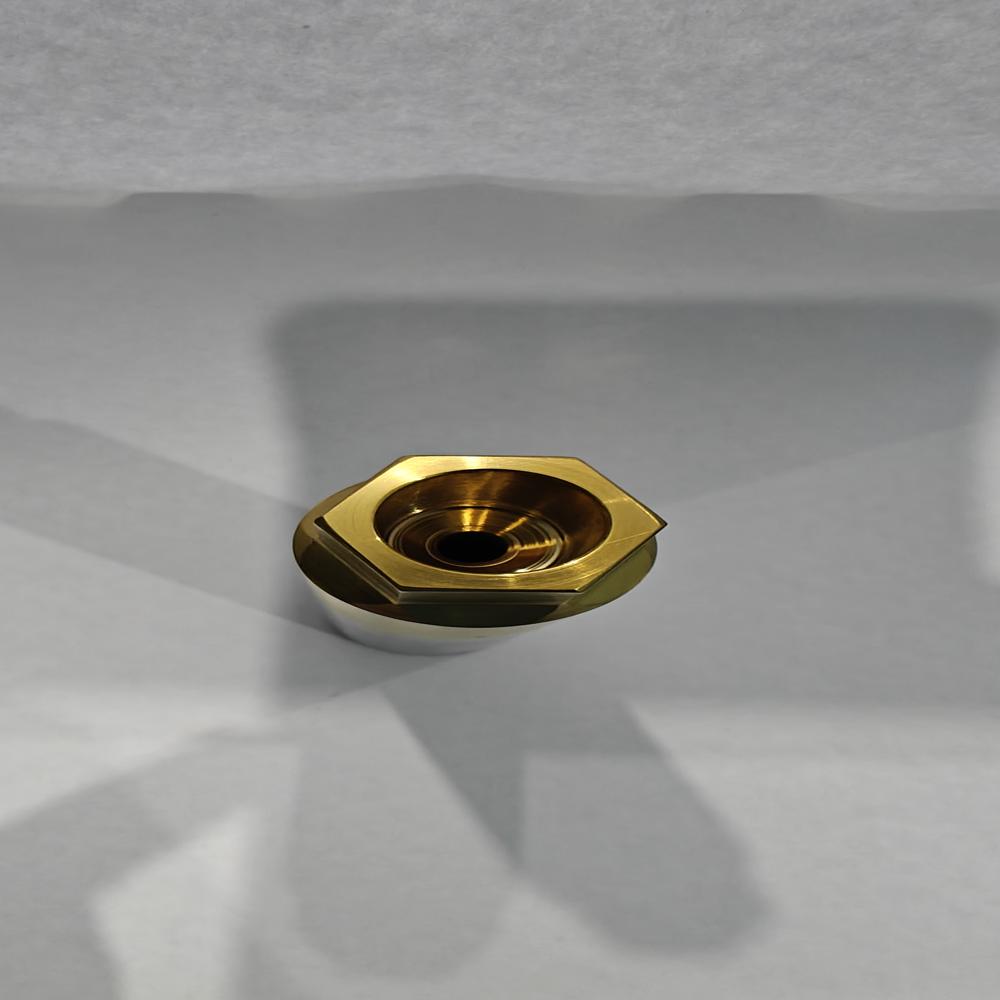

PUNCH STN 04 D 26/HEX19.20/14.10 IDX15X100 M42

PUNCH STN 04 D 26/HEX19.20/14.10 IDX15X100 M42 Specification

- Color

- Golden

- Features

- HSS

- Operate Method

- Manual

- Usage

- Industrial

- Size

- Different Available

- Material

- High Speed Steel

PUNCH STN 04 D 26/HEX19.20/14.10 IDX15X100 M42 Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 20 Days

About PUNCH STN 04 D 26/HEX19.20/14.10 IDX15X100 M42

HEX PUNCH OD 26/HEX19.20/HEX LENGTH14.10/ID 15/100MM M42 WITH PVD COATING- Outer Diameter (OD): 26 mm

- Hex Size: 19.20 mm (Across Flats)

- Hex Length: 14.10 mm

- Inner Diameter (ID): 15 mm

- Overall Length: 100 mm

- Material: M42 High-Speed Steel (HSS)

- Coating: PVD (Physical Vapor Deposition)

Material & Coating Details:

-

M42 HSS:

- A cobalt-bearing high-speed steel with excellent hardness, wear resistance, and red hardness.

- Ideal for high-performance cutting tools and punches that require durability.

- Composition: 8-10% cobalt, which improves heat resistance.

- Hardness: Can reach 67-70 HRC after heat treatment.

-

PVD Coating:

- Increases tool life by reducing wear and friction.

- Provides a low coefficient of friction, improving chip evacuation.

- Enhances surface hardness, making the punch resistant to abrasion.

- Common PVD coatings include TiN (Titanium Nitride), TiAlN (Titanium Aluminum Nitride), and AlCrN (Aluminum Chromium Nitride)specific coating type depends on application requirements.

Applications:

- Used in cold forging and precision machining.

- Suitable for high-strength materials, stainless steel, and other alloys.

- Common in automotive, aerospace, and industrial manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Punch Category

NUT FORMER PUNCH DIA 16.90/15.90/14.65/13.40/8.40x102MM WITH ALCRONA BLACK COATING

Price 863.0 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : 6466 HRC

Usage : Industrial

Size : Different Available

HOLE PUNCH DIA 10/9.15/9.10x110MM WITH PVD TIN COATING HSS M42

Price 580.0 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Material : High Speed Steel

Usage : Industrial

Size : 10/9.15/9.10x110MM

HOLE PUNCH DIA 12.90/11.90/6.75/6.90x101MM WITH PVD TIN COATING HSS M42

Price 605.00 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Material : High Speed Steel

Usage : Industrial

Size : 12.90/11.90/6.75/6.90x101MM

HOLE PUNCH DIA 10/9.15/5.10x110MM WITH PVD TIN COATING HSS M42

Price 581.00 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : High

Material : High Speed Steel

Usage : Industrial

Size : 10/9.15/5.10x110MM

Send Inquiry

Send Inquiry