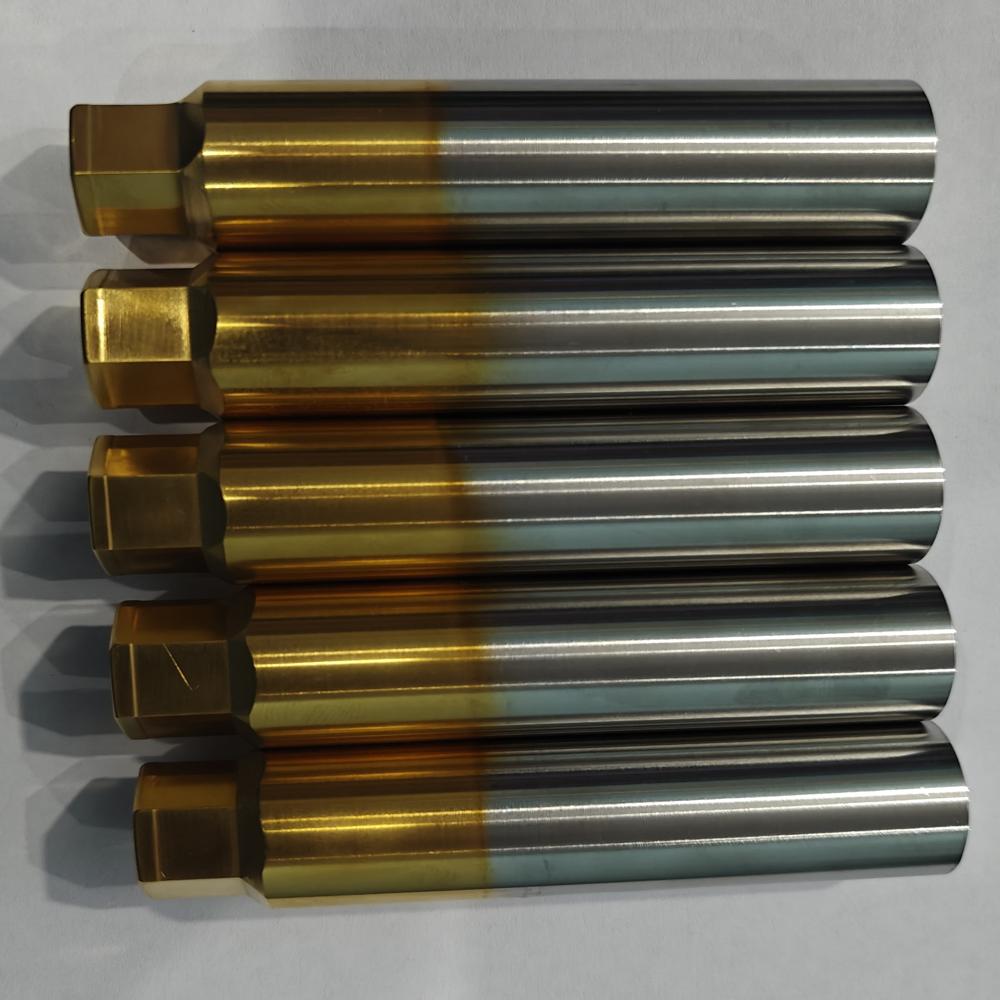

NUT FORMER IST PUNCH DIA 8/7.15/4.05x81MM WITH PVD TIN COATING HSS M42

Product Details:

- Usage Industrial

- Click to View more

NUT FORMER IST PUNCH DIA 8/7.15/4.05x81MM WITH PVD TIN COATING HSS M42 Price And Quantity

- 434.0 INR/Unit

- 10 Unit

NUT FORMER IST PUNCH DIA 8/7.15/4.05x81MM WITH PVD TIN COATING HSS M42 Product Specifications

- Industrial

NUT FORMER IST PUNCH DIA 8/7.15/4.05x81MM WITH PVD TIN COATING HSS M42 Trade Information

- 50 Unit Per Month

- 20 Days

- All India

Product Description

-

HSS M42:

- Contains 8-10% cobalt, ensuring high red-hardness and toughness.

- Resistant to chipping and cracking under high-stress operations.

- Suitable for punching and forming high-strength materials like stainless steel, titanium, and alloy steels.

-

PVD TiN Coating:

- Provides low friction and reduced material adhesion, improving tool life.

- Enhances wear and heat resistance, allowing longer running cycles without degradation.

- Increases surface hardness, ensuring precision in high-speed forming.

- Extended Tool Life: The PVD TiN coating significantly increases durability.

- High Precision: Ensures consistent punch quality for uniform nut forming.

- Excellent Wear & Heat Resistance: Withstands intense forming pressure and temperature.

- Reduced Friction & Material Build-Up: Enhances efficiency and prevents tool sticking.

Nut Former 1st Punch 8/7.15/4.05 81mm with PVD TiN Coating, HSS M42

1. Overview:

This Nut Former 1st Punch, made from HSS M42 (High-Speed Steel, M42 Grade), is specifically designed for cold and warm forging applications in nut forming machines. The PVD TiN (Titanium Nitride) coating enhances its wear resistance, hardness, and longevity, making it ideal for high-speed and high-pressure metal forming.

2. Technical Specifications:

| Parameter | Details |

|---|---|

| Material | HSS M42 (High-Speed Steel, M42 Grade) |

| Diameters | 8.00 mm / 7.15 mm / 4.05 mm |

| Overall Length | 81 mm |

| Coating | PVD TiN (Titanium Nitride) |

| Hardness | Approx. 67-70 HRC |

| Surface Hardness (with TiN) | ~2300 HV (Vickers Hardness) |

| Wear Resistance | High (due to TiN coating) |

| Heat Resistance | Excellent (M42 can withstand up to 1100C) |

3. Material & Coating Details

4. Applications

Nut Forming Machines Used as a 1st punch in multi-station cold and warm forming processes.

Bolt & Fastener Manufacturing Essential for high-precision nut and bolt production.

Automotive & Aerospace Industries Used in forming high-strength fasteners for industrial applications.

Heavy-Duty Industrial Forming Suitable for high-speed production lines with continuous operation.

5. Benefits

6. Comparable Alternatives

| Alternative | Key Benefits |

|---|---|

| HSS M35 | Lower cobalt content but still effective for forming. |

| Uncoated HSS M42 | Same base material but lacks the friction-reducing benefits of TiN. |

| TiAlN Coating | Better at extreme high temperatures but slightly less wear-resistant than TiN. |

| Solid Carbide Punch | Harder and longer-lasting, but more brittle and expensive than HSS. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry